Description

If you’re looking for a tablet press that will help you test a new product or concept before it goes into production, you’ve found it. Capable of producing tablets of various sizes and in small quantities, the TDP 1.5 is certainly the device that suits your needs. Manufactured to meet the needs of laboratory and development needs, rather than for large scale production, the TDP 1.5 is still capable of anything from just a few to 5,000 tablets per hour.

The main benefit of this tablet press lies in its versatility coupled with a strong feature set and the premium quality of its construction. The latter guarantees excellent reliability. For these reasons, the TDP 1.5 is a popular option for use in research facilities, laboratories, food technology applications, pharmaceutical developments, chemical plants and hospitals, or any facility where overall flexibility, ease of use, good volume and quality are required.

Main advantages of the TDP 1.5

- Lightweight for its class

- Compact dimensions

- Fast and reliable

- Flexible output

- Electrically or manually operated

- Broad raw material compatibility

- Low maintenance

- Low consumption

- Works with 200g minimum amount of raw materials

- Compresses tablets of any shape

- Adjustable tablet diameter, depth and hardness

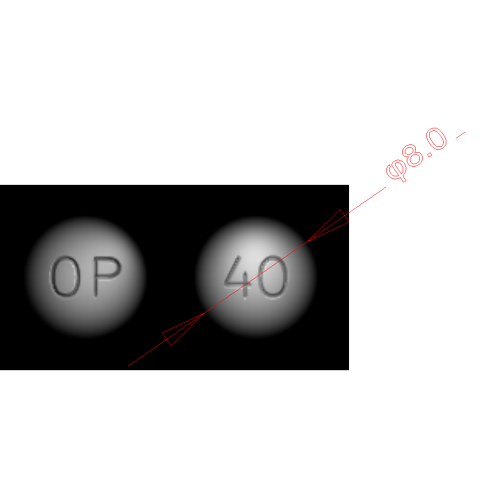

- Option for stamp design on the tablets

- Suitable for motifs or continuous foil

Features of the TDP 1.5 Tablet Press

The TDP 1.5 is a single punch tablet press and has a maximum pressure of 15 kN. It was designed to be installed on a bench, but can also be easily removed and relocated. The device offers an adjustable filling depth with a maximum depth of 12mm, and can produce tablets up to 8mm in diameter and 6mm thick. The TDP 1.5 does not limit you to the standard molded products. By simply changing the shape in the device, you can press almost any shape of tablet. In addition, you can change the density of the tablet to be made. The machine also offers the option of stamping designs onto the top of the tablet, either to give it an attractive finish or for identification purposes. Due to the attractiveness of the TDP 1.5 for R &

This press is compatible with most of the granulated or powdered materials but is not designed for use with overly wet substances or super fine powders.

Designed with utility in mind, the TDP 1.5 is known as a highly functional machine that can be either electrically powered or run in manual mode. In manual mode, the press is driven by just one crank. Combined with a small base and light weight for a press of this specification, this versatility makes the TDP 1.5 more flexible and portable than other machines with equivalent overall performance.

Technical specifications

The dimensions of the TDP 1.5 are 700mm x 400mm x 800mm, and the weight is 55 kg. It has a tower speed of 1,400 rpm while running on electricity and the motor has a maximum power of 0.75 kW for single phase use and 0.55 kW for three phase use. The device can run on mains voltage which is either 110V or 220V.

The TDP 1.5 tablet press in operation

This press is remarkably easy to use, and despite its compact size, it offers a number of advantages that set it apart from comparable devices.

To operate the press by hand, simply load the raw produce into the cone-shaped container, then grasp the wheel and turn it gently. Tablets will then appear and are ready to be bottled. It’s a very simple process that anyone can quickly learn. If you’re just making a few pills, you’ve got the hang of it. This is a key feature of this press. Alternatively if you require a larger batch of tablets then simply plug into the outlet and it will operate quickly and efficiently on electric power.

Manufacturing and testing of products often requires the development of products with similar but somewhat varied formulations. The TDP 1.5 has a number of features that make it particularly suitable for this purpose.

First of all, it is a highly efficient press, which makes it possible to get more tablets from a given amount of raw materials with little use. Second, a special advantage is that the TDP 1.5 can be operated with a minimum amount of only 200g of material. This is really ideal for research and educational work where you just want to squeeze a few pretest tablets. Later, when you have identified promising formulas, use the TDP 1.5 for larger batches to run full tests.

Third, the TDP 1.5 allows to ensure the effectiveness of the testing process by ensuring that it is easy to see what has been produced. This is crucial to ensure that the right formula is provided to the right subject. The TDP 1.5 addresses this problem due to the ease with which you can change the shape, size or design of the tablets you are making. Provided you have a mold for the design you would like to make, you can switch styles instantly by detaching the funnel and unscrewing the feeder mechanism.

You can also quickly change the density and weight of the tablets on the TDP 1.5, just by unscrewing a nut on the connecting rod and you change the pressure of the TDP 1.5.

Maintaining the TDP 1.5 is an undemanding endeavor. Nothing more than once or twice a month to inspect and lubricate and oil the moving parts. The equipment was built to make this process as easy as possible.

Reviews

There are no reviews yet.